- HJEM

- MARKEDER

- vores produkter

-

-

- PUMPER

- EXCENTRISKE SKRUEPUMPER

- PERISTALTISKE PUMPER

- DOSERING AF PERISTALTISKE PUMPER

- GEAR PUMPER

- LOBEPUMPER - SPILAD/INDUSTRI

- DOSERING – STEMPEPUMPER

- DOSERING – MEMBRANSPUMPER

- LUFTDREVNE MEMBRANSPUMPER

- KLOKAK - SELVSPUGENDE PUMPER

- DRÆNING - SKRUE CENTRIFUGALPUMPER

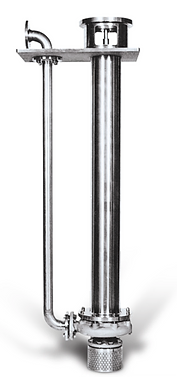

- GRUNDVANDSPUMPER

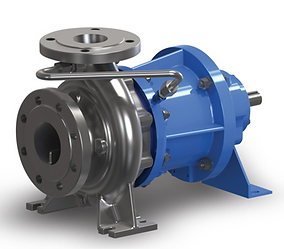

- MAGNETISKE PUMPER

- VANDFORSYNING

- VORTEX PUMPER

- VÆSKE VAKUUMPUMPER

- TØNDEPUMPER

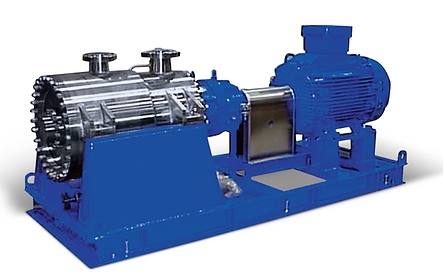

- CENTRIFUGALPUMPER I FLERE trin

- EXCENTRISK SKIVEPUMPE/TÆTNINGSFRI

- SIDEKANAL BLÆSERE

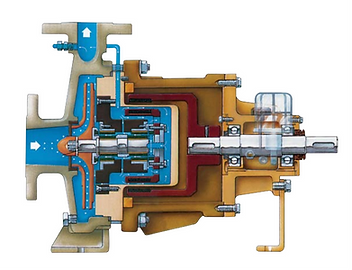

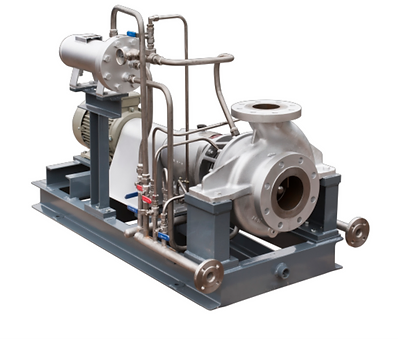

- CENTRIFUGALPUMPER

- VING PUMPER – MAG DRIVE PUMPE

- CENTRIFUGALT MAG-DREV

- HCM – CENTRIFUGAL MAG DRIVE

- PERIFERE OG GEARPUMPER

- MAG-M CENTRIFUGALPUMPER

- REGENERATIV TURBINEPUMPE

- CENTRIFUGALE PUMPER-FØDEVARER

- SELER

- CHOPPER PUMPER – PS-SERIEN

- FILTER

- PUMPER

-

-

- PUMPESTATIONER

- Online butik

- OM OS

- KONTAKT