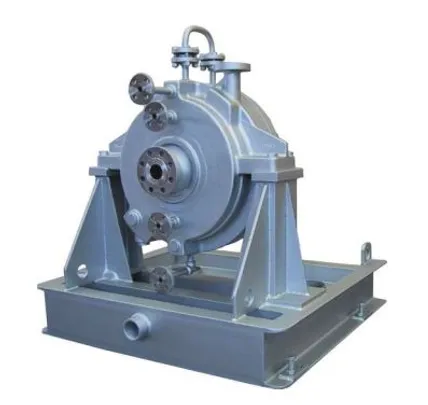

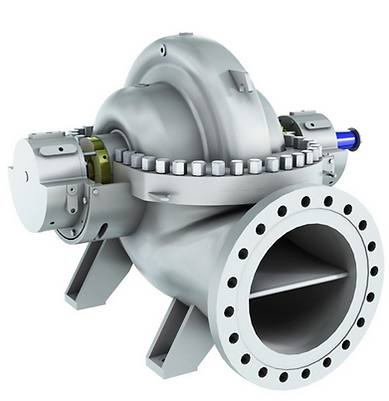

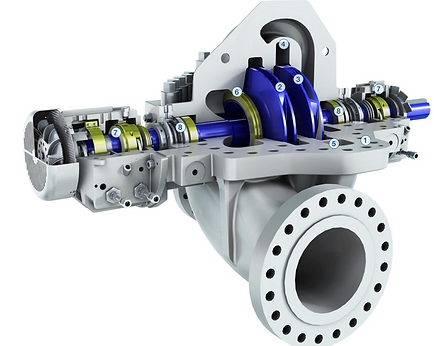

OH1 foot mounted flexibly coupled

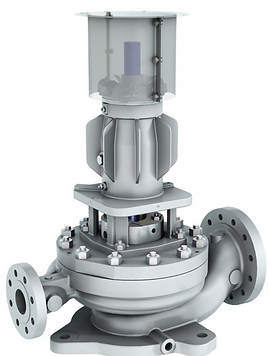

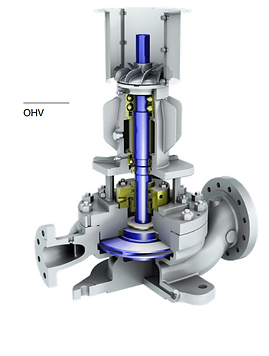

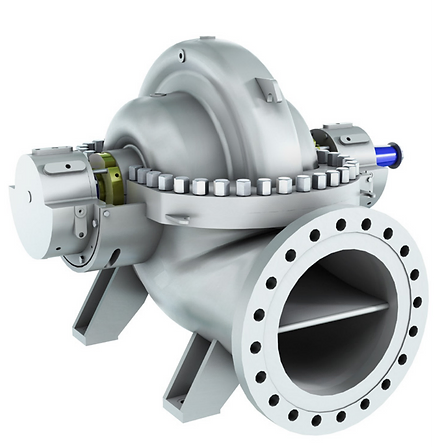

Single-stage centrifugal process pumps, available in a variety of construction materials to suit different applications and equipped with single, double or cartridge mechanical seals. The pumps are characterized by a different design.

Applications: Clean and slightly contaminated liquids

Viscous liquids

Fibrous slurries

Large solids containing liquids

Gas containing liquids and self-priming applications

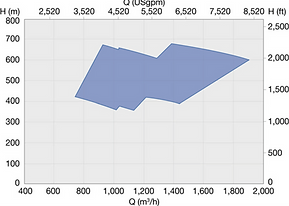

Q [m3/h]: Up to 11 0000 (4500)

H [m]: ≤ 160 (320)

p [bar]: 16 (60 bar)

T [°C]: 180 (from -90 to 180°C)

flanges standard ANSI B 16.5

50÷60Hz

ATEX

special executions on job