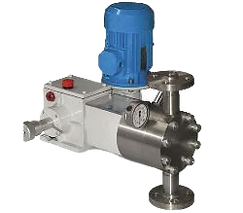

■ Stroke length: 15 mm

■ Stroke length adjustment range: 0 – 100 %

■ Stroke adjustment: manual with self-locking turntable in steps of 0.2 % (optionally with

electric actuator or steering drive)

■ Measurement reproducibility is better than ± 1 % within the 10-100 % stroke volume adjustment range

under certain defined conditions and with correct installation

■ Wet materials: Stainless steel 1.4571/1.4404, special materials are available on request

■ High performance oxide ceramic piston

■ A wide range of powerful versions are available: Three-phase standard motor, 1-phase AC motor,

motors for use in areas subject to explosion and different flange designs for use in customer specific

engines

■ Degree of protection IP 55

■ Very rigid fiberglass reinforced plastic housing with excellent chemical resistance

■ Provide suitable overload protection in all piston dosing pumps during installation for safety reasons

Capacity:

Capacity: : 0-940 l/h

Max pressure: 0.7-940 bar

– High suction capacity

– High dosing precision

– Stroke regulation with minimal flow pulsation

– Robust mechanism for continuous work

– Regulation: 0-100 %

- Dosing and mixing can be done in powder or in liquid Batch-wise

High accuracy: linearity ± 1%, repeatability ± 3%, stable accuracy ± 1%

Applications:

Chemistry, agriculture, petrochemical industry, water treatment, solvent, oils, alkalis, dye, resin, polymers, plastics, adhesives and cleaning agent.

– Can handle high viscosity (55,000 cps) and chemicals

MATERIALS

Cylinder: AISI 316 L.

Piston: AISI 316 L.

Sealing: Packing seals / Aramid graphite / PTFE

Valve (body): AISI 316 L.

Valve (ball): AISI 316

Block: Gray cast iron