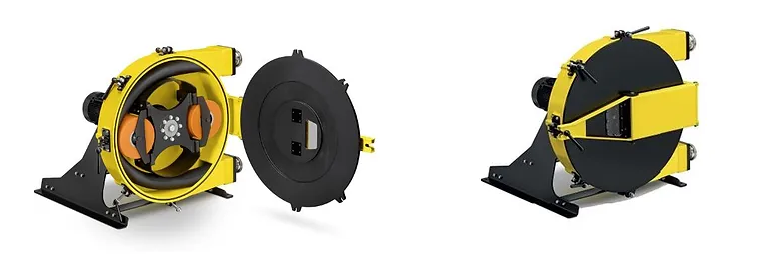

The operating principle of a peristaltic pump has its advantage in its simplicity.

A tubular element with exact dimensions connected in the pump housing. Produced in

different types of elastomer or thermoplastic.

When this tubular element is compressed by the rotary function of the rotor and

associated rollers or shoes, it restores its original shape and creates a

vacuum, in this way sucks the liquid. The fluid enters the cavity as

formed by the rollers pressing on the pipe, and gently pushed to its outlet

following the roll.

Therefore, the pump is a positive displacement volumetric pump with outstanding

characteristics.

Benefits:

Abrasion resistant:

Very high suction power and capacity

The pumps can withstand dry running

No need for valves

Applications where valves are a problem in direct contact with viscous media and solids

substances that can block the valves.

No mechanical seal:

Mechanical seals are a problem with sticky and highly viscous media, with hose pumps this is avoided.

Mode of action:

The "shoe" is rotated using the motor, the shoes stand 180 degrees apart. The hose is pressed by the shoe, the medium is pushed forward after compression and a continuous vacuum is created at the inlet of the pump, the medium is transported towards the outlet of the hose. The pump housing contains lubricating fluid that reduces friction between the shoe and the hose. The advantage of transporting the medium with the hose is that it is trotted in a hygienic way, the medium is only in contact with the rubber band. The peristaltic pump was well suited to several applications.

Examples:

• Water and sewage treatment: Dosing of flocculation coagulant, sludge transfer, ferric chloride

• Food industry: Ketchup, Mustard, fruit juice.

• Chemical industry: acids, alcohols, soap, non-aromatic solvents (petrol)

• Water samples: Collection of water samples

• Mineral processing: Tenants up to 50-60,000 cp. Cement production, chemicals.

• Paper industry: Chemicals

• Agriculture: Fertilizer, slurry (soft manure and water eg ammonia NH4 + ), liquid sugar.

Industrial peristaltic pump, reinforced rubber impact system for working pressure up to 15 bar. Capacity up to 60,000 l/h. Flange connections in ANSI or DIN.