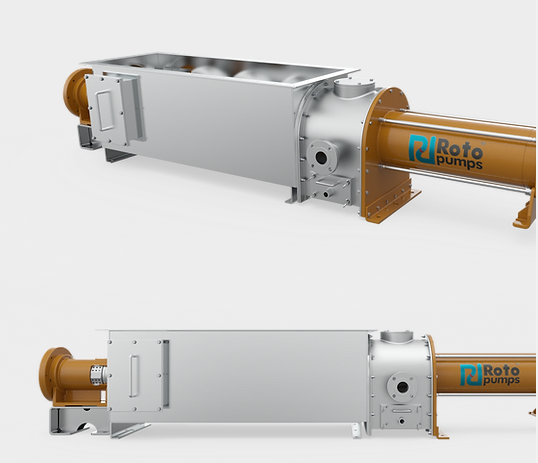

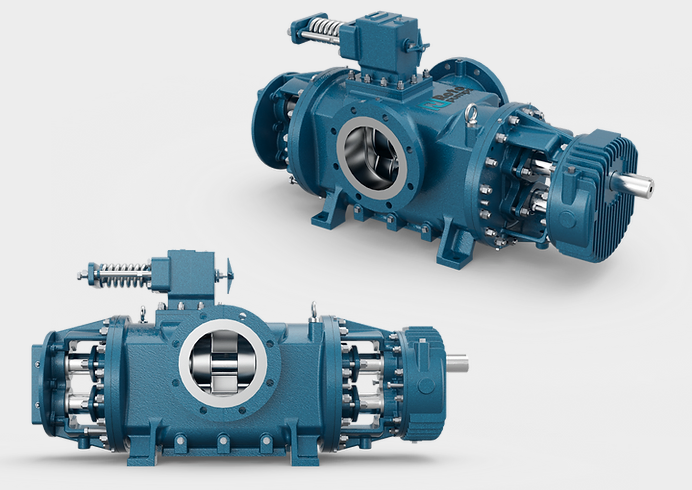

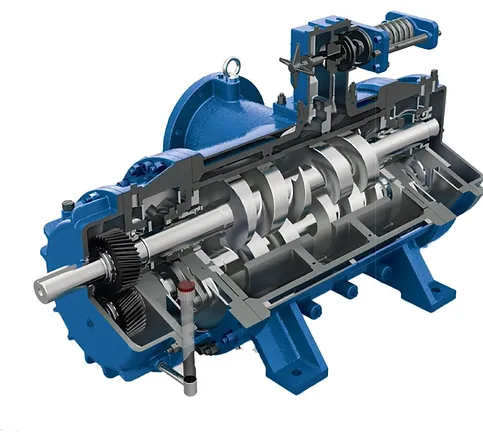

TWIN SCREW PUMPS

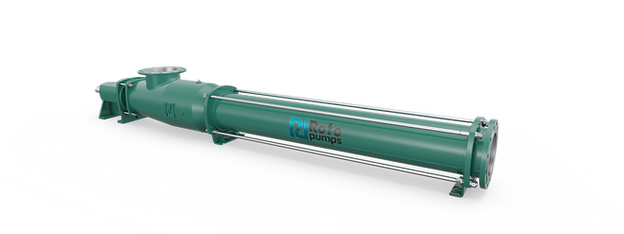

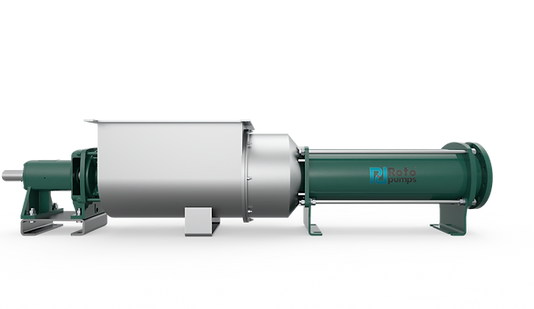

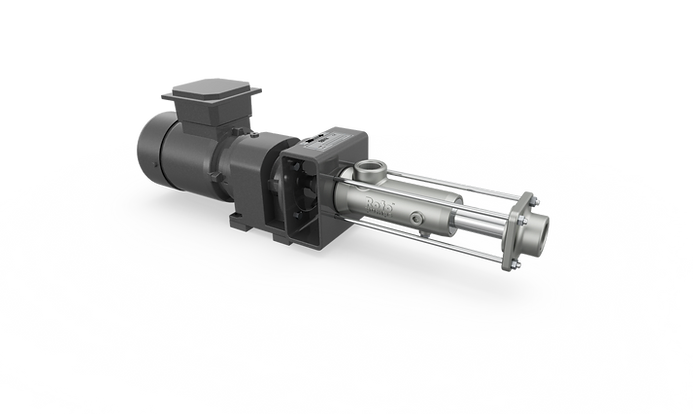

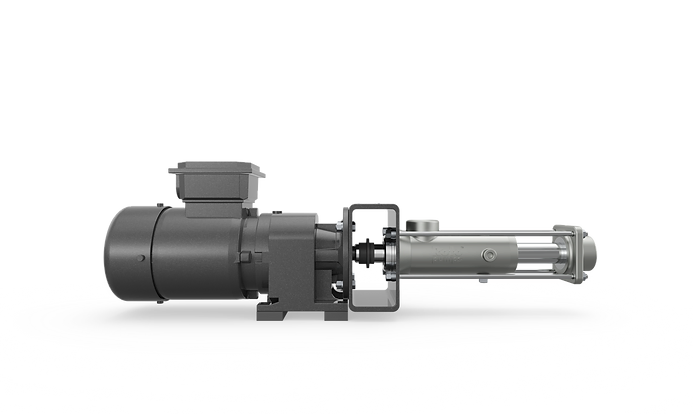

Horizontal internally stored Twin Screw Pumps are chosen where the fluids are clean and have lubricating properties. These pumps are designed with internal bearings that are lubricated by the pump medium itself. The suction and discharge ports are in-line.

The mechanical seals are supplied as standard scope of delivery. Gland packing option can also be offered as per application requirements. These pumps are equipped with relief valves and are suitable for 100 % bypasses. These pumps are also available in standard foot-mounted configuration with sump heating as an option.

Characteristics and benefits:

Standard API676

Long and trouble-free service life due to the absence of metal-to-metal contact between the pump elements. It can even go dry for a limited period of time.

No axial thrust Dual flow of fluid in opposite direction balances axial thrust.

Higher volumetric efficiency due to special double profile of screw flanks.

High cavitation-free suction lift due to low NPSH (R).

Broader compliance with API 676, 2nd edition.

Self-priming and capable of handling trapped air/vapour/gas due to positive displacement action and is inherently self-priming.

Uniform Metered Flow Being a positive displacement pump, head is independent of speed and capacity is approximately proportional to speed.

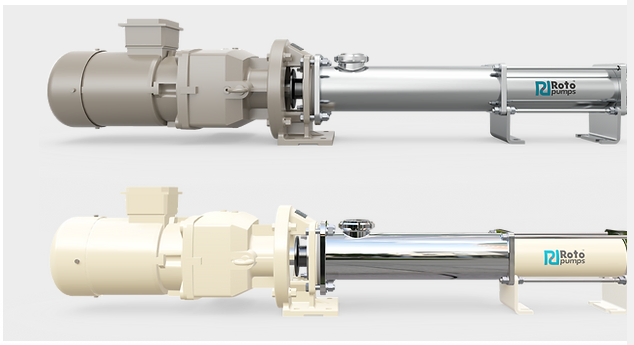

Capable of handling a wide range of fluids, lubricating/non-lubricating as well as aggressive fluids can be handled due to the choice of different designs and materials of construction.

Safe to operate has built in relief valve, designed to bypass up to 100 % capacity.

Benefits:

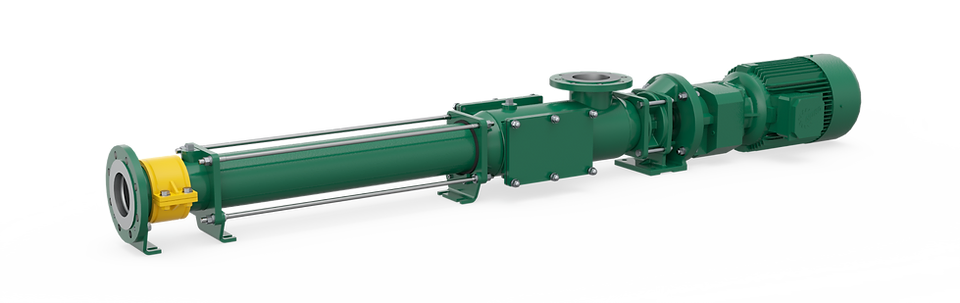

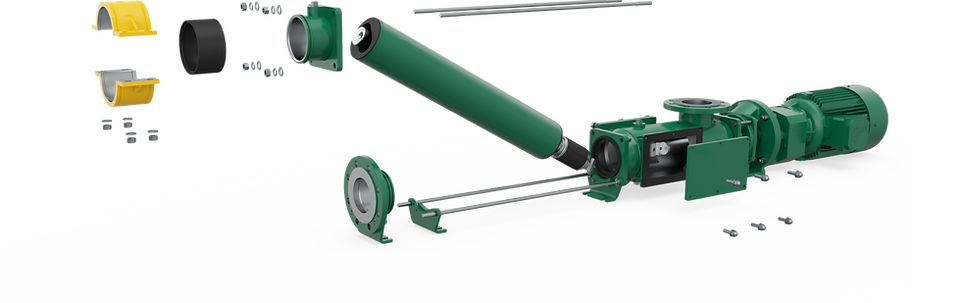

– Screw profile

– Robust pump housing

– Various types of mechanical seals API 682

– Spherical ball bearing

– Synchronized gearbox

– Replacement of wearing parts

– Built-in safety valve

Capacity:

– Capacity: Up to 1000m3/h

– Working pressure: Up to 40bar