Roto pumps – Heavy Duty Pumps – Eccentric screw pumps

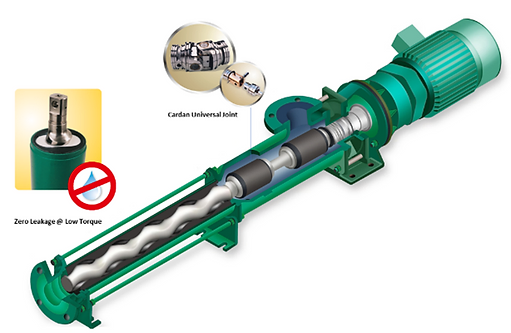

Eccentric screw pumps excel for handling different types of liquids and demanding applications. Eccentric screw pumps fall under the category "displacement pumps". The main element of the pump is a helical rotor with an annular cross-section and protected all around by a fixed stator. The pump's rotor-stator geometry and internal components have a major impact on efficiency and performance.

Important internal components affect pump efficiency

The pumps are assembled according to the building block principle, with optimal interference fit between rotor and stator to reduce friction between the parts, which ensures minimal contact with well-developed and tested surface treatment. This is important for increasing efficiency and reduces energy consumption in the eccentric screw pump. The main element of the pump is a helical rotor with an annular cross-section and protected all around by a fixed stator.

Power transmission in the pump cardan joint ensures gentle operation and increases reliability.

Well-designed shaft seals prevent leakage, help improve volumetric efficiency and reduce energy output.

Correct adjustment and quality of the bearings minimizes energy loss and improves the overall effect of the pump.

Certain models can also be supplied with a storage tray over 30 kW.

Applications: sludge, delicate liquids to abrasive media, from thin-flowing and viscous liquids, fibrous and solid particles.

By accurately calculating pump efficiency and implementing strategies that provide proper pump sizing, material selection, regular maintenance, and advanced control systems, industries can achieve higher performance levels, reduce operating costs, and contribute to sustainable fluid handling practices. Fluid Handling Practices for Eccentric Screw Pumps.

Norditec supplier of pumps, valves and instrumentation.

Read the article in Teknisk Ukeblad

Download!